A runway (RWY) is a strip of land on an airport, on which aircraft can take off and land. Runways may be a man-made surface (often asphalt, concrete, or a mixture of both) or a natural surface (grass, dirt, or gravel).

Orientation and dimensions

Runways are generally numbered according to their magnetic heading (the takeoff direction it is "pointing towards"). The runway number is the whole number nearest one-tenth the magnetic azimuth of the centerline of the runway, measured clockwise from the magnetic north. Each digit is pronounced separately for clarity in radio communications. For example, Runway Three Six would be aligned in roughly a 360 degrees direction (magnetic north), Runway Nine would be used for a runway with a 94 degree-alignment (close to magnetic east), and Runway One Seven for 168 degrees. Each runway can be used in either direction, and hence has two numbers, each 180° apart. Thus, Runway One Zero (100°) becomes Runway Two Eight (280°) when used in the opposite direction and Runway One Eight (180°) becomes Runway Three Six (360°). Runways in North America that lie within the Northern Domestic Airspace are, because of the magnetic north pole, usually numbered according to true north.

In International Civil Aviation Organization (ICAO) and some United States military (such as Edwards Air Force Base) airports, numbers for runways less than 100° include the leading "zero", for example, Runway Zero Two or Runway Zero One Left. However in the United States at most civil aviation airports, numbers for runways less than 100° are often given as single digits; for instance, Runway Nine or Runway Four Right. This also includes some military airfields such as Cairns Army Airfield. This American anomaly may lead to inconsistencies in conversations between American pilots and controllers in other countries. It is very common in a country such as Canada for a controller to clear an incoming American aircraft to, for example, Runway 04, and the pilot read back the clearance as Runway 4. Users of flight simulation programs may note that those of American origin might apply U.S. usage to airports around the world. For example Runway 05 at Halifax (CYHZ) will appear on the FS program as the single digit 5 rather than 05.

Runway designations do change over time. Because the magnetic poles slowly drift on the Earth's surface, but the runways stay fixed, the magnetic bearing will change. Depending on the airport location and how much drift takes place, it may be necessary over time to change the runway designation. As runways are designated with headings rounded to the nearest 10 degrees, this will affect some runways more than others. For example,if the magnetic heading of a runway is 276 degrees , it would be designated Runway 28. If the magnetic heading changed upwards by 5 degrees, the Runway would still be Runway 28. If on the other hand the original magnetic heading was 284 (Runway 28), and the heading increased by only two degrees to 286, the runway should become Runway 29. Because the drift itself is quite slow, runway designation changes are relatively uncommon, and not welcomed, as they do require an accompanying change in a wide range of navigational and descriptive documents.

If there is more than one runway pointing in the same direction (parallel runways), each runway is identified by appending Left (L), Center (C) and Right (R) to the number — for example, Runways One Five Left (15L), One Five Center (15C), and One Five Right (15R). Runway Zero Two Left (02L) becomes Runway Two Zero Right (20R) when used in the opposite direction (derived from adding 18 to the original number for the 180 degrees when approaching from the opposite direction).

At large airports with more than three parallel runways (for example, at Los Angeles International Airport in Los Angeles, California, Detroit Metropolitan Wayne County Airport in Romulus, Michigan,Hartsfield-Jackson International Airport in Atlanta, Georgia, and Denver International Airport), some runway identifiers are shifted by 10 degrees to avoid the ambiguity that would result with more than three parallel runways. In Los Angeles, this system results in Runways Six Left, Six Right, Seven Left, and Seven Right, even though all four runways are exactly parallel (approximately 69 degrees).

At Dallas-Fort Worth International Airport, there are five parallel runways, named 17L, 17C, 17R, 18L, and 18R.

For fixed-wing aircraft it is advantageous to perform take-offs and landings into the wind to reduce takeoff roll and reduce the ground speed needed to attain flying speed. Larger airports usually have several runways in different directions, so that one can be selected that is most nearly aligned with the wind. Airports with one runway are often constructed to be aligned with the prevailing wind.

Runway dimensions vary from as small as 245 m (804 ft) long and 8 m (26 ft) wide in smaller general aviation airports, to 5,500 m (18,045 ft) long and 80 m (262 ft) wide at large international airports built to accommodate large passenger jets.

Placement and grouping

Two runways pointing in the exact same direction are classed as dual or parallel runways depending on the separation distance. In some countries, flight rules mandate that only one runway may be used at a time under certain conditions (usually adverse weather) if the parallel runways are too close to each other.

Declared distances

- TORA

- Takeoff Run Available - The length of runway declared available and suitable for the ground run of an airplane taking off.

- TODA

- Takeoff Distance Available - The length of the takeoff run available plus the length of the clearway, where provided (the clearway length allowed must lie within the aerodrome or airport boundary. According to JAR TODA is the lesser of TORA plus clearway or 1.5 times TORA).

- ASDA

- Accelerate Stop Distance Available - The length of the takeoff run available plus the length of the stopway, where provided.

- LDA

- Landing Distance Available - The length of runway which is declared available and suitable for the ground run of an airplane landing.

"Sections" of a runway

- The Runway Strip is the cleared, grassy area around the paved runway. It is kept free from any obstacles that might impede flight or ground roll of aircraft, although the grass is not always necessarily in good condition. The grass is often marked with white cones or gables.

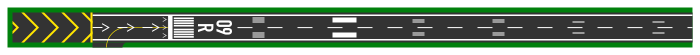

- The Runway is the entire paved surface, which typically features threshold markings, numbers, centerlines, and overrun areas at both ends.

- Blast pads, also known as overrun areas or stopways, are often constructed just before the start of a runway where jet blast produced by large planes during the takeoff roll could otherwise erode the ground and eventually damage the runway. Overrun areas are also constructed at the end of runways as emergency space to slowly stop planes that overrun the runway on a landing gone wrong, or to slowly stop a plane on an aborted take-off or a take-off gone wrong. Blast pads are often not as strong as the main paved surface of the runway and are marked with yellow chevrons. Planes are not allowed to taxi, take-off or land on blast pads, except in an emergency.

- Displaced thresholds may be used for taxiing, takeoff, and landing rollout, but not for touchdown. A displaced threshold often exists because obstacles just before the runway, runway strength, or noise restrictions may make the beginning section of runway unsuitable for landings. It is marked with white paint arrows that lead up to the beginning of the landing portion of the runway.

Runway lighting

History

The first runway lighting appeared in 1930 at Cleveland Municipal Airport (now known as Cleveland Hopkins International Airport) in Cleveland, Ohio.

Technical specifications

Runway lighting is used at airports which allow night landings. Seen from the air, runway lights form an outline of the runway. A particular runway may have some or all of the following.

- Runway End Identification Lights (REIL) Unidirectional (facing approach direction) or omnidirectional pair of synchronized flashing lights installed at the runway threshold, one on each side.

- Runway end lights A pair of four lights on each side of the runway On precision instrument runways, these lights extend along the full width of the runway. These lights show green when viewed by approaching aircraft and red when seen from the runway.

- Runway Edge Lights White elevated run the length of the runway on either side. On precision instrument runways, the edge-lighting becomes yellow in the last 2,000 ft (610 m) of the runway. Taxiways are differentiated by being bordered by blue lights, or by having green centre lights, depending on the width of the taxiway, and the complexity of the taxi pattern.

- Runway Centerline Lighting System (RCLS) Lights embedded into surface of the runway at 50 ft (15 m) intervals along the runway centerline on some precision instrument runways. White except last 3,000 ft (914 m), alternate white and red for next 2,000 ft (610 m) and red for last 1,000 ft (305 m).

- Touchdown Zone Lights (TDZL) This consists of rows of white light bars (with three in each row) on either side of the centerline over the first 3,000 ft (914 m) (or to the midpoint, whichever is less) of the runway.

- Taxiway Centerline Lead-Off Lights Installed along lead-off markings, alternate green and yellow lights embedded into runway pavement. It starts with green light about runway centerline to the position of first centerline light beyond holding position on taxiway.

- Taxiway Centerline Lead-On Lights Installed same way as Taxiway centerline Lead-Off Lights.

- Land and Hold Short Lights A row of white pulsating lights installed across the runway to indicate hold short position on some runways which are facilitating LAHSO operations.

- Approach Lighting System or ALS, is a lighting system installed on the approach end of an airport runway and consists of a series of lightbars, strobe lights, or a combination of the two that extends outward from the runway end.

According to Transport Canada's regulations, the runway-edge lighting must be visible for at least 2 miles (3 kilometres). Additionally, a new system of advisory lighting, Runway Status Lights, is currently being tested in the United States.

The edge lights must be arranged such that:

- the minimum distance between lines is 75 ft (23 m), and maximum is 200 ft (61 m);

- the maximum distance between lights within each line is 200 ft (61 m);

- the minimum length of parallel lines is 1,400 ft (427 m);

- the minimum number of lights in the line is 8.[1]

Control of Lighting System Typically the lights are controlled by a control tower, a Flight Service Station or another designated authority. Some airports/airfields (particularly uncontrolled ones) are equipped with Pilot Controlled Lighting, so that pilots can temporarily turn on the lights when the relevant authority is not available. This avoids the need for automatic systems or staff to turn the lights on at night or in other low visibility situations. This also avoids the cost of having the lighting system on for extended periods. Smaller airports may not have lighted runways or runway markings. Particularly at private airfields for light planes, there may be nothing more than a windsock beside a landing strip.

Runway markings

There are various runway markings and signs on any given runway. Larger runways have a distance remaining sign (black box with white numbers). This sign uses a single number to indicate the thousands of feet remaining, so 7 will indicate 7,000 ft (2,134 m) remaining. The runway threshold is marked by a line of green lights.

There are three types of runways:

- Visual Runways are used at small airstrips and are usually just a strip of grass, gravel, asphalt or concrete. Although there are usually no markings on a visual runway they may have threshold markings, designators, and centerlines. Additionally, they do not provide an instrument-based landing procedure; pilots must be able to see the runway to use it. Also, radio communication may not be available and pilots must be self-reliant.

- Non-precision instrument runways are often used at small-medium size airports. These runways, depending on the surface, may be marked with threshold markings, designators, centerlines, and sometimes a 1,000 ft (305 m) mark (known as an aiming point, sometimes installed at 1,500 ft (457 m)). They provide horizontal position guidance to planes on instrument approach via Non-directional beacon (NDB), VHF omnidirectional range (VOR), Global Positioning System, etc.

- Precision instrument runways, which are found at medium and large size airports, consist of a blast pad/stopway (optional, for airports handling jets), threshold, designator, centerline, aiming point, and 500 ft (152 m), 1,000 ft (305 m)/1,500 ft (457 m), 2,000 ft (610 m), 2,500 ft (762 m), and 3,000 ft (914 m) touchdown zone marks. Precision runways provide both horizontal and vertical guidance for instrument approaches.

National variants

- In Australia, Canada, Japan, the United Kingdom, as well as some other countries all 3-stripe and 2-stripe touchdown zones for precision runways are replaced with one-stripe touchdown zones.

- In Australia, precision runways consist of only one 1-stripe touchdown zone, aiming point, and one 1-stripe touchdown zone. Furthermore, all non-precision and visual runways lack an aiming point.

- Some European countries replace the aiming point with a 3-stripe touchdown zone.

- Runways in Norway have yellow markings instead of the usual white ones. This also occurs on some airports in Japan. The yellow markings are used to ensure better contrast against snow.

- Runways may have different types on each end. To cut costs, many airports do not install precision guidance equipment on both ends. Runways with one Precision end and any other type of end can install the full set of touchdown zones, even if some are past the midpoint. If a runway has Precision markings on both ends, touchdown zones within 900 ft (274 m) of the midpoint are omitted, to avoid pilot confusion over which end the marking belongs to.

Pavement

The choice of material used to construct the runway depends on the use and the local ground conditions. Generally speaking, for a major airport, where the ground conditions permit, the most satisfactory type of pavement for long-term minimum maintenance is concrete. Although certain airports have used reinforcement in concrete pavements, this is generally found to be unnecessary, with the exception of expansion joints across the runway where a dowel assembly, which permits relative movement of the concrete slabs, is placed in the concrete. Where it can be anticipated that major settlements of the runway will occur over the years because of unstable ground conditions, it is preferable to install asphaltic concrete surface, as it is easier to patch on a periodic basis. For fields with very low traffic of light planes, it is possible to use a sod surface.

The development of the pavement design proceeds along a number of paths. Exploratory borings are taken to determine the subgrade condition, and based on relative bearing capacity of the subgrade, different pavement specifications are established. Typically, for heavy-duty commercial aircraft, the pavement thickness, no matter what the top surface, varies from as little as 10 inches (25 centimetres) to as much as 4 ft (1 m), including subgrade.

Historically, airport pavements have been designed by two methods. The first, Westergaard, is based on the assumption that the pavement is an elastic plate supported on a heavy fluid base with a uniform reaction coefficient known as the K value. Experience has shown that the K values on which the formula was developed are not applicable for newer aircraft with very large footprint pressures.

The second method is called the California bearing ratio and was developed in the late 1940s. It is an extrapolation of the original test results, which are not applicable to modern aircraft pavements or to modern aircraft landing gear. Some designs were predicated on the melding of these two design theories; they are empirical in nature and are not reliable. Another, more recent, method is an analytical system based on the introduction of vehicle response as an important design parameter. Essentially it takes into account all factors, including the traffic conditions, service life, materials used in the construction, and, especially important, the dynamic response of the vehicles using the landing area.

Because airport pavement construction is so expensive, every effort is made to minimize the stresses imparted to the pavement by aircraft. Manufacturers of the larger planes design landing gear so that the weight of the plane is supported on larger and more numerous tires. Attention is also paid to the characteristics of the landing gear itself, so that adverse effects on the pavement are minimized. However, in the final analysis, if plane weights continue to increase as they have in the past, it will be necessary to provide substantially stronger pavements than those that are generally in use in Europe and the United States. Sometimes it is possible to reinforce a pavement for higher loading by applying an overlay of asphaltic concrete or portland cement concrete that is suitably bonded to the original slab.

Posttensioning concrete has been developed for the runway surface. This permits the use of thinner pavements and should result in longer concrete pavement life. Because of the susceptibility of thinner pavements to frost heave, this process is generally applicable only where there is no appreciable frost action.

Pavement surface

Runway pavement surface is prepared and maintained to maximise friction for wheel braking. To minimize hydroplaning following heavy rain, the pavement surface is usually grooved so that the surface water film flows into the grooves and the peaks between grooves will still be in contact with the aircraft tires. To maintain the macrotexturing built into the runway by the grooves, maintenance crews engage in Airfield rubber removal in order to meet required FAA friction levels.

Active runway

The active runway is the runway at an airport that is in current use for takeoffs and landings. Since takeoffs and landings are usually done as close to "into the wind" as possible, wind direction generally determines the active runway (or just the active in aviation slang).

Selection of the active runway, however, depends on a number of factors. At a non-towered airport, pilots usually select the runway most nearly aligned with the wind, but they are not obliged to use that particular runway. For example, a pilot arriving from the east may elect to land straight in to an east-west runway despite a minor tailwind or significant crosswind, in order to expedite his arrival, although it is recommended to always fly a regular traffic pattern to more safely merge with other aircraft.

At controlled airports, the active is usually determined by a tower supervisor. However, there may be constraints, such as policy from the airport manager (calm wind runway selection, for example, or noise abatement guidelines) that dictate an active runway selection that isn't the one most nearly aligned with the wind.

At major airports with multiple runways, the active could be any of a number of runways. For example, when O'Hare (ORD) is landing on 27R and 32L, departures use 27L and 32R, thus making four active runways. When they're landing on 14R and 22R, departures use 22L and 9L, and occasionally a third arrival runway, 14L, will be employed, bringing the active runway count to five.

At major airports, the active runway is based on existing weather conditions (visibility and ceiling, as well as wind, and runway conditions such as wet/dry or snow covered), efficiency (ORD can land more aircraft on 14R/32L than they can on 9L/27R), traffic demand (when a heavy departure rush is scheduled, a runway configuration that optimizes departures vs arrivals may be desirable), and time of day (ORD is obliged to use runway 9L/27R during the hours of roughly midnight to 6 a.m. due to noise abatement).

Runway Length

Although runway length may be of some academic interest, in terms of usability for air carrier operations, a runway of at least 6,000 ft (1,829 m) in length is usually adequate for aircraft weights below approximately 200,000 pounds (90,718 kilogrammes). Larger aircraft including widebodies (Boeing 747, 767, 777, and 787; Airbus A310, A330, A340, A350, and A380; McDonnell-Douglas DC-10 or MD-11; and the Lockheed L1011) will usually require at least 8,000 ft (2,438 m) at sea level and somewhat more at higher altitude airports. International widebody flights may also have landing requirements of 10,000 ft (3,048 m) or more and takeoff requirements of 13,000 ft (3,962 m)+.

At sea level, 10,000 ft (3,048 m) can be considered an adequate length to accommodate virtually any aircraft. For example, at O'Hare International Airport, when landing simultaneously on 22R and 27L or parallel 27R, it is routine for arrivals from the Far East which would normally be vectored for 22R (7,500 ft (2,286 m)) or 27R (8,000 ft (2,438 m)) to request 27L (10,000 ft (3,048 m)). It is always accommodated, although occasionally with a delay.

Any given aircraft will need a longer runway at a higher altitude due to decreased density of air at higher altitudes, which reduces lift and engine power. For example, New York JFK is at sea level, while Denver is over 5,000 feet, so the same aircraft with an identical load will require a longer runway at Denver. An aircraft will also require a longer runway in hotter or more humid conditions (see density altitude). Most commercial aircraft carry manufacturer's tables showing the adjustments required for a given temperature.

See also

Notes

References

- United States Areonautical Information Manual - Federal Aviation Administration - published yearly

- United States Airport Facility Directory - Federal Aviation Administration - published every 56 days.

No comments:

Post a Comment